May Safety Update:

Injuries Year to Date 2020: 4

Injuries through May 2019 5

May Safety Topic of the Month – Parking Lot Safety

Remember – Parking lot speed limit is 5mph!

Cloth mask Information and Care Instructions

Please read through the following information about caring for a cloth mask:

- Wash your mask after every use. Cloth masks are machine washable.

(Masks have been washed prior to being given to you but washing it again wouldn’t hurt)

- Make sure your mask is fully dry before putting it on. Cloth masks are dryer safe but can be hung to dry to maintain better shape.

- Know the signs of when its time to stop reusing a mask

(If your mask is damaged or permanently soiled, discard the mask)

- Practice safe handling when putting the mask on and taking it off.

- Wash your hands before and after putting a mask on.

- Wash your hands before and after taking a mask off.

- Make sure the mask fits securely when putting it on.

- Refrain from touching the outside of the mask when taking it off.

- Practice safe storage of the mask.

- Store the mask in a safe and clean place before putting it on (i.e. a clean zip lock bag that is ONLY used for clean masks)

- Place the used mask in a separate location until it can be washed (i.e. a closed Tupperware container)

May Quality Update

- PP100 = Problems per 100. This means for every 100 windows we produce how many errors we made?

- Problems per 100 Goal is =<1.7 for 2020.

- Currently for 2020 we’re holding at 1.8 (1.76) YTD

- Jan = 1.7

- Feb = 1.8

- Mar = 1.9

- Apr = 1.7

- May = 1.7

- Last 3 weeks we’ve averaged 1.4

- Problems per 100 Goal is =<1.7 for 2020.

- In-Plant Testing

- We’re sill drainage testing every day now as of the first of April. This has highlighted some opportunities for us regarding sealing consistency.

- Currently of all the sill drainage testing we do we’re passing 92% of the work tested.

- The goal for passing drainage testing must be at =>98%.

- Our previous record for most consecutive days without a failed test was 8 days. As of 5/12 we are at 1 day w/out fails.

- Audit Compliance

- Process audits are strong predictors of whether our windows will be of high quality. If we adhere to procedures, we can rely that our windows will match the customer order and pass any water testing and visual inspections from our customers. They can also be influenced because we’re observing real time.

- Goal is =>98% compliance

- Process compliance:

- YTD process compliance for the factory is 94%

- Jan = 92%

- Feb = 92%

- Mar = 94%

- Apr = 94%

- May = 95%

- Product Audits are lag indicators that show how well we already performed (they also can’t be influenced because it’s already done).

- Product compliance:

- Goal is >=98%

- YTD product compliance for the factory is 95%

- Jan = 85%

- Feb = 96%

- Mar = 97%

- Apr = 93%

- May = 95%

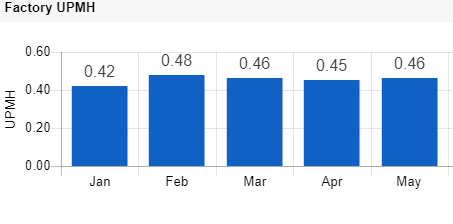

Efficiency

Goal is 0.48 UPMH

Team, you have seen on your end of line board in your department a sheet to track any non-value-added activities that are included in your task. I am asking for your help identifying them. Are your tools presented? Do you spend time looking for items to complete your task? Do you have to take unnecessary steps to find. Help us help you!

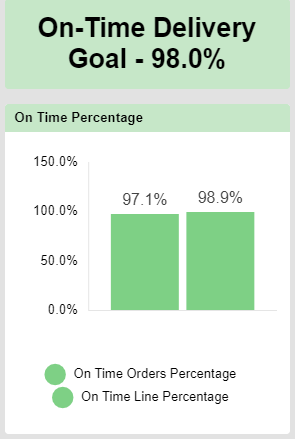

On time Completion

We are just shy of our on-time delivery goal of 98%. I know we can do better than this.

We control how much business comes through Paradigm’s door! On time product to our customer and high quality (TFQ) will retain and create new customers.

If it’s worth doing its worth doing right!

May Cost Update

- As we navigate through uncharted territory, with the rest of the world, it is hard to predict rest of the year.

- We do have initiatives in place to aid orders including strategic promotions with our partners (customers)

- Efforts from our sales team have shown some results and over last 5-6 days we have been seeing increase in incoming orders.

- More than ever we need to function as a TEAM in staying safe and shipping quality product on time.